The manufacture of food products is regulated globally, and food manufacturers have sophisticated laboratories and established procedures to ensure the safety of food products — and to develop products with desirable characteristics. Increasingly, the most desired characteristics for many foods are shifting from simple sweetness to flavor + nutritional benefits.

However, foods are shipped around the globe and often subjected to a wide range of conditions (heat, light, oxygen) that can catalyze changes in food quality, resulting in a decrease in taste, nutritional value, and the generation of unhealthy byproducts.

The evaluation of the safety, freshness and quality of foods in the marketplace, as opposed to at the point of manufacture, is a matter of increasing international interest. Efforts to date have primarily focused on food safety, especially the detection of deleterious microbes and microbial toxins, and the production certain byproducts (e.g. histamine) that can have immediate and disastrous effects.

In addition to acute food safety issues, there is increasing awareness of the need to monitor foods for retention of beneficial qualities (e.g. antioxidant activity), as well as the development of characteristics that either reduce flavor and/or have detrimental long-term health effects (e.g. rancidity). Although there are established laboratory procedures to accurately measure antioxidants, and oxidative byproducts and other food quality characteristics, they are need to be performed in a laboratory setting and are not amenable to “field testing” of foods.

Recognizing the need for rapid, simple, inexpensive and reliable methods to assess food quality in the field, the Oxford Biomedical Research Food Science Division was established. Our novel products for these applications are based on over 30 years of developing and manufacturing assays for antioxidants and lipid peroxidation for the medical research community. We have now tailored selected test procedures for analysis of foods, and have rigorously validated them vs. well-establish reference methods.

Biomarkers of Food Quality and Freshness:

Our initial products for the assessment of food quality include:

Oil Polarity: Frying oil can go rancid due to many factors, including overheating, prolonged use, and contamination from foods. Our oil polarity testing products include novel liquid phase (qualtitative) and dipstick (semi-quantitative) tests to quickly measure the change in polarity of a cooking oil due to oxidation and hydrolysis from heating, also known as hydrolytic rancidification. (FS62 Oil Polarity Test)

TBARS: Fats, oils, and other lipids react with oxygen and decompose to give aldehydes that are associated with “off-flavor” odors in lipids and lipid-containing foods, including in meats, dairy products and other foods (including favorings). Our Malonaldehyde Quantitation Kit is the first rapid TBARS assay that does not require heat or strong acids. It can be performed room temperature, requires no preliminary extraction or distillation and eliminates many interferences found in older methods. (FS50 TBARS for Food an Beverages)

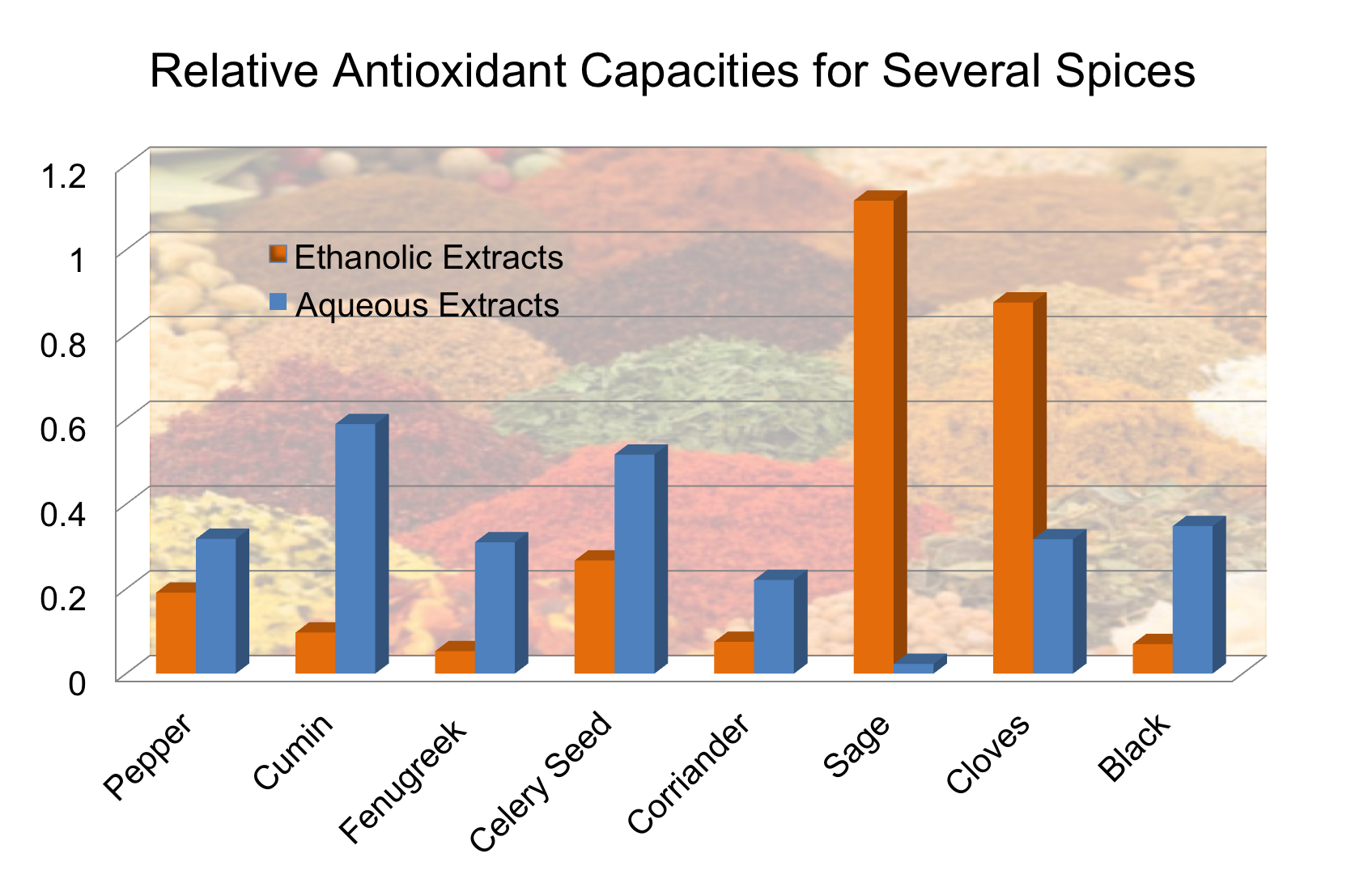

Total Antioxidant Capacity: Antioxidants help preserve food freshness, and many of them have multiple health benefits for humans. Our colorimetric method (LINK) for measuring Total Antioxidant Capacity (TAC) has several advantages over older antioxidant assays and can be performed very quickly in a non-laboratory setting. (FS02 CUPRAC Antioxidant Test)

Histamine: Histamine is found in a wide range of foods. Significant amounts of histamine can be generated by microbial decomposition of foods (spoilage). Our immunoassay for histamine is unique in that it does not require pretreatment of the sample to form a histamine derivative, thus making the method simpler AND less prove to variations due to incomplete conversion to a derivative. (Histamine Test for Foods and Beverages)